As with most technologies used in the consumer space, they take a number of years to gestate before they mature enough and gain visibility to end users. Capacitive-based multi-touch technology burst into the consumer conscience with the introduction of the iPhone. Dozens of companies have since entered the market to provide capacitive touch technologies to support new designs and applications. The capabilities that capacitive touch technology can support, such as improved touch sensing for multiple touches, detecting and filtering unintended touches (such as palm and cheek detection), as well as supporting a stylus, continues to evolve and improve.

Capacitive touch enjoys a very strong position providing the technology for multi-touch applications; however, there are other technologies that are or will likely be vying for a larger piece of the multi-touch pie. A potential contender is the vision-based multi-touch technology found in the Microsoft Surface. However, at the moment of this writing, Microsoft has indicated that it is not focusing its effort for the pixel sense technology toward the embedded market, so it may be a few years before the technology is available to embedded developers.

The $7600 price tag for the newest Surface system may imply that the sensing technology is too expensive for embedded systems, but it is important to realize that this price point supports a usage scenario that vastly differs from a single user device. First, the Surface provides a 40 inch diagonal touch/display surface that four people can easily access and use simultaneously. Additionally, the software and processing resources contained within the system are sized to handle 50 simultaneous touch points. Shrink both of these capabilities down to a single user device and the pixel sense technology may become quite price competitive.

Vision-based multi-touch works with more than a user’s fingers; it can also detect, recognize and interact with mundane, everyday objects, such as pens, cups, paint brushes, as well as touch interface specific objects such as styli. The technology is capable, if you provide enough compute capability, to distinguish and handle touches and hovering of fingers and objects over the touch surface differently.I’m betting as the manufacturing process for the pixel sense sensors matures, the lower price points will make a compelling case for focusing development support to the embedded community.

Resistive touch technology is another multi-touch contender. It has been the work horse for touch applications for decades, but its ability (or until recently, lack of) to support multi-touch designs has been one of its significant shortcomings. One advantage that resistive touch has enjoyed over capacitive touch for single-touch applications is a lower cost point to incorporate it into a design. Over the last year or so, resistive touch has evolved to be able to support multi-touch designs by using more compute processing in the sensor to resolve the ghosting issues in earlier resistive touch implementations.

Similar to vision-based multi-touch, resistive touch is able to detect contact with any normal object because resistive touch relies on a mechanical interface. Being able to detect contact with any object provides an advantage over capacitive touch because capacitive touch sensing can only detect objects, such as a human finger or a special conductive-tipped stylus, with conductive properties that can draw current from the capacitive field when placed on or over the touch surface. Capacitive touch technology also continues to evolve, and support for thin, passive styli (with an embedded conductive tip) is improving.

Each technology offers different strengths and capabilities; however, the underlying software and embedded processors in each approach must be able to perform analogous functions in order to effectively support multi-touch applications. A necessary capability is the ability to distinguish between explicit and unintended touches. This capability requires the sensor processor and software to be able to continuously track many simultaneous touches and assign a context to each one of them. The ability to track multiple explicit touches relative to each other is necessary to be able to recognize both single- and multi-touch gestures, such as swipes and pinches. Recognizing unintended touches involves properly ignoring when the user places their palm or cheek over the touch area as well as touching the edges of the touch surface with their fingers that are gripping the device.

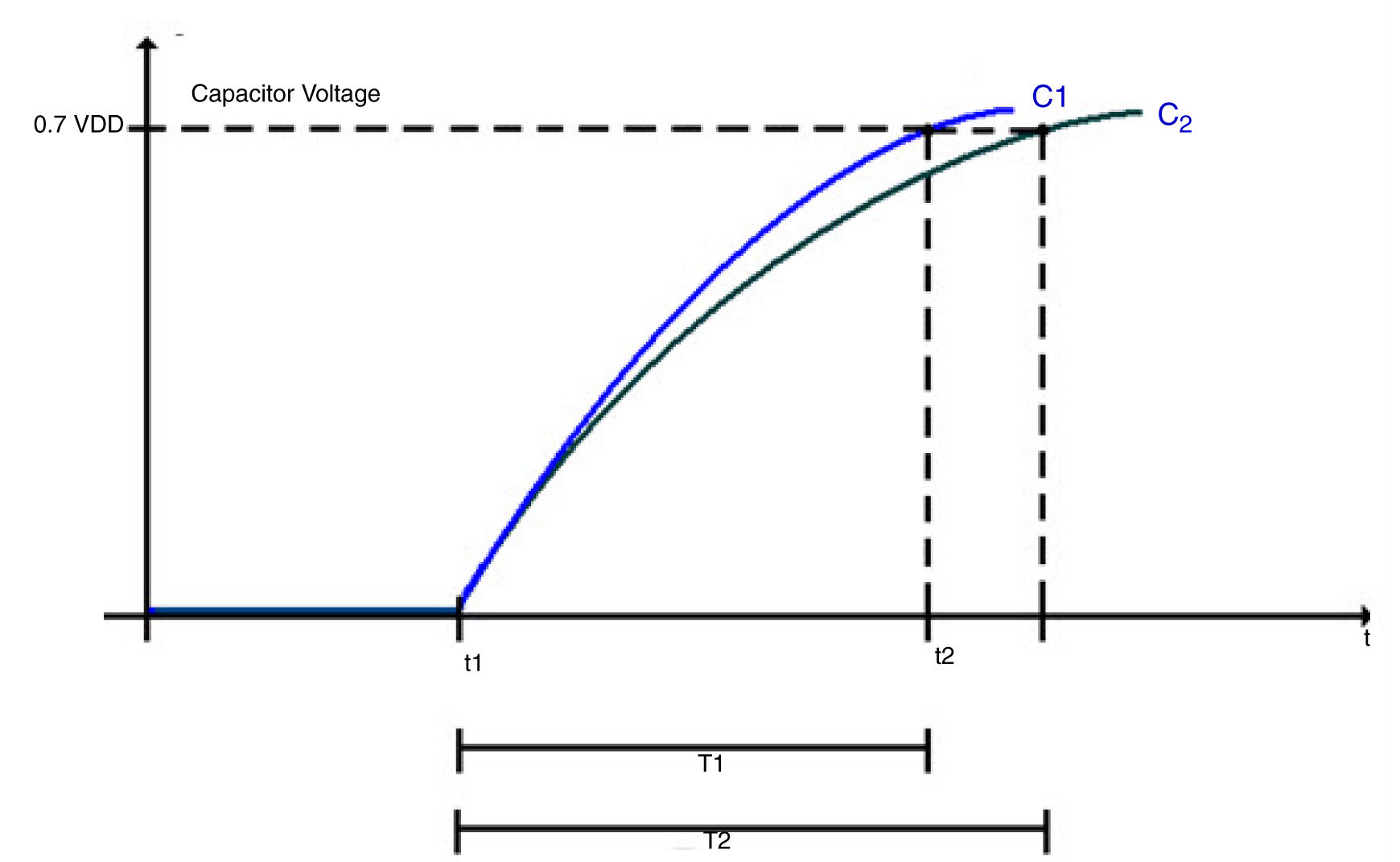

A differentiating capability for touch sensing is minimizing the latency between when the user makes an explicit touch and when the system responds or provides the appropriate feedback to that touch. Longer latencies can affect the user’s experience in two detrimental ways in that the collected data for the touch or gesture has poor quality or the delay in feedback confuses the user. One strategy to minimize latency is to sample or process less points when a touch (or touches) is moving; however, this risks losing track of small movements that can materially affect analyzing the user’s movement such as when writing their signature. Another strategy to accommodate tracking the movement of a touch without losing data is to allow a delay in displaying the results of the tracking. If the delay is too long though, the user may try to compensate and try to restart their movement – potentially confusing or further delaying the touch sensing algorithms. Providing more compute processing helps in both of these cases, but it also increases the cost and energy draw of the system.

While at CES, I experienced multi-touch with all three of these technologies. I was already familiar with the capabilities of capacitive touch. The overall capabilities and responsiveness of the more expensive vision-based system met my expectations; I expect the price point for vision-based sensing to continue its precipitous fall into the embedded space within the next few years. I had no experience with resistive-based multi-touch until the show. I was impressed by the demonstrations that I saw from SMK and Stantum. The Stantum demonstration was on a prototype module, and I did not even know the SMK module was a resistive based system until the rep told me. The pressure needed to activate a touch felt the same as using a capacitive touch system (however, I am not an everyday user of capacitive touch devices). As these technologies continue to increasingly overlap in their ability to detect and appropriately ignore multiple touches within a meaningful time period, their converging price points promise an interesting battle as each technology finds its place in the multi-touch market.